Marine biofouling is a huge problem for boat owners but also for the shipping industry across the globe. The build up of fouling organisms on hulls, rudders and propellers leads of higher fuel consumption and reduced boat performance.

Traditionally, antifouling paints have been used which contain biocides to prevent this biofouling but in this blog we talk about antifouling technology past present and future and why innovative new antifouling technologies are needed to combat marine pollution.

The issues with current antifouling coatings

‘Antifouling paints that are meant to end up in the water cannot be part of a sustainable future,’ Joke Wezenbeek from the Dutch National Institute for Public Health and the Environment (RIVM).

Although progress has been made in reducing the amount of biocidal antifouling coatings leaching into our oceans there is certainly much more that can be done. Biocides not only affect the marine fouling organisms they are intended for but also all other marine life, particularly those larger animals further up the food chain from marine biofouling organisms and, ultimately, humans.

The 2001 ban by the International Maritime Organization (IMO) on environmentally harmful tributyltin (TBT) was a huge step in the right direction, but the modern copper alternatives still cause excessive off-target effects. Therefore, innovative antifouling technologies are needed to reduce the environmental impact of antifouling whilst still maintaining antifouling performance.

Heavy metals and microplastics

Chemically active paints containing copper or zinc are toxic to and prevent the binding of marine biofouling to boat hulls, preventing build-up of fouling that can hamper boat performance and fuel efficiency. However, these metal are released from antifouling coatings into the sea either by leaching or on fouling release coatings and can cause mutations in marine organisms and toxicity in other sea life as well as releasing huge amounts of microplastics into our oceans.

Environmentally friendly ultrasonic antifouling – the future is now!

Ultrasonic antifouling is an environmentally benign antifouling system and one of only a few marine antifouling solutions already available that doesn’t rely on antifouling coatings or antifouling paint.

Ultrasonic antifouling uses transducers attached to the hull of the boat which emit high frequency waves. These waves cause a vibration through the hull which creates areas of negative and positive pressure, resulting in micro jets surrounding the boats hull leading to the destruction of the single cell micro organisms like algae. Removing algae prevents the attachment of other organisms in the food chain which feed on algae from building up on your boat hull.

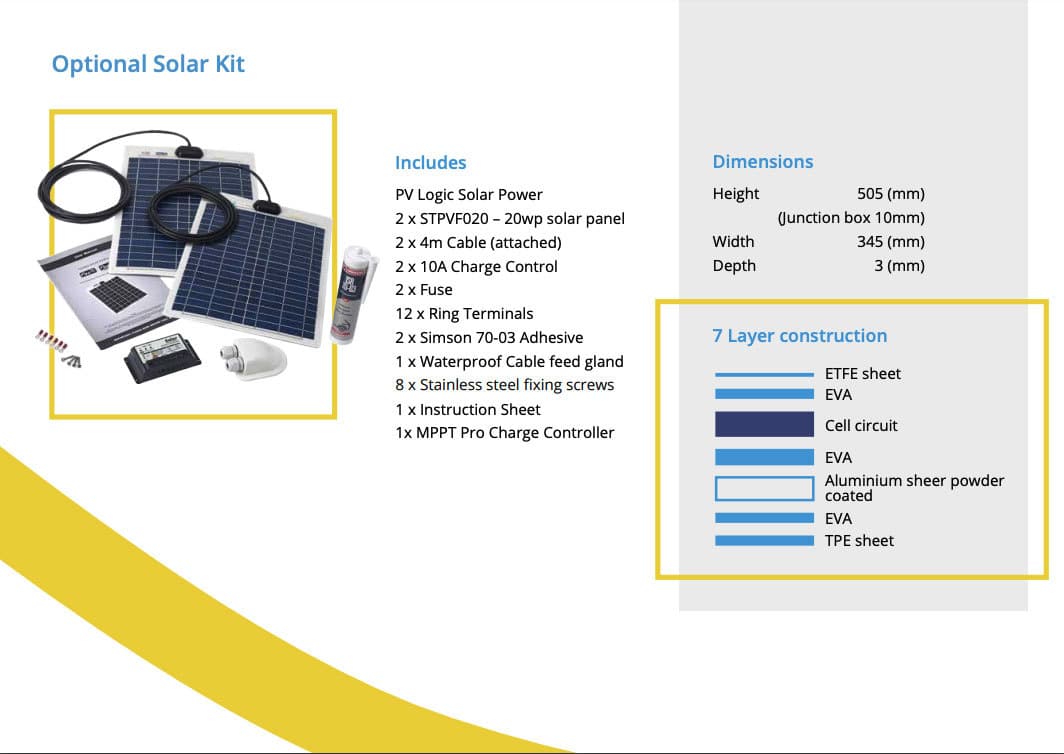

Our ultrasonic antifouling systems here at Electronic Fouling Control come with the option of solar power to help reduce energy consumption and environmental impact even further.

Environmentally friendly antifouling coatings in development

The European Commission has been pushing member states and industry to work harder on finding new antifouling technology to replace copper and invest in substitution. Our previous blog on environmentally friendly antifouling options gives an in-depth view of the issues with traditional antifouling paints, below we focus on advances in marine antifouling coatings and technologies and the bottom paint alternatives of the future.

You may have noticed that companies who do use metal-based marine antifouling coatings have started to produce products with a lower leach rate. However, this doesn’t prevent the release of these paints into the environment when replacing antifouling coatings or solve the problem in ‘self-polishing’ antifouling release coatings which slough away into the water as the boat moves.

Fermentation and enzyme technology

The Danish biotech company Cysbio are developing a product from Eelgrass – a marine plant found commonly on shorelines. They are using fermentation to derive zosteric acid which they are then able to use in their marine antifouling coatings in place of the traditional copper and zinc with no harmful impact on the environment. The fermentation chemical production process also produces less greenhouse gases that traditional chemical manufacturing – a win win for the environment.

Similarly enzyme technology utilises enzymes as the biocide release mechanism. The a harmless substrate such as starch is broken down to release hydrogen peroxide which prevents marine biofouling.

Biochemical and Biomimetic coatings

Products such as Selektope (more commonly known as Medetomidine), developed by pharmaceutical giant Astra Zeneca, make use of clever biochemistry. Selektope stimulates octopamine receptor in young mollusks and causing them to be repelled from the hull surface.

Selektope is completely harmless to the marine environment and works against barnacles and mussels but isn’t effective against algae. Therefore paint producing companies still need to add in an algaecide to prevent the attachment and growth of algaes on the boat hulls but this product is in production.

Alternatively, some companies are taking inspiration from other sea life an mimicking how these creatures prevent algal growth from attaching. Coatings applied as self-adhesive sheets mimic the spines of sea urchins, using nylon hairs to help prevent the attachment of biofoul. These sheets can be effective for over five years. Furanones produced by some seaweed stop marine organisms from attaching, interfering with the signalling that allows bacteria to clump together at the start of the fouling process. These natural chemicals are being researched as potential new additives for antifouling coatings.

Another coating option is inspired by the carnivorous pitcher plant. When rain falls on its leaves the solid surface turns into a sea of water to help insects slide into its pitchers where they are digested. This type of hull coating has a surface made up of microscopically small tendrils with immobilised lubricant weaved between them which works once the coating is in contact with the water.

Finally, a coating inspired by shark skin is also on the cards. Sharks have little to no issues with marine biofouling so scientists are looking into ways by which the same arrangement of ridges could be used to prevent fouling on boat hulls.

silicone and hydrogel marine antifouling coatings

Nanotech Marine’s have developed an antifouling coating that uses silicone which is already available. The silicone creates a surface with very low friction, making it so slippery that biofouling organisms simply cannot stick to the hull. Hydrogel coatings absorb water to create a barrier layer which prevents fouling from attaching to the boat hull.

The use of biocide-free coatings like silicone sound good but they only work on boats which are used regularly above 10 knots and not boats stored on a mooring or in a marina for weeks or months on end. This is because the technology relies on the movement of the boat through the water to ‘wash off’ any marine biofouling that is trying to attach – utilising a more natural antifouling processes. Furthermore, hydrogel coatings could also contribute to microplastic release into the oceans.

Barriers to a more sustainable future for marine coatings

As you can see, there are lots of exciting developments in antifouling coatings and future steps towards efficient and environmentally friendly antifouling coatings are being taken. However, there are certainly still key barriers to a more sustainable future for antifouling coatings that need to be overcome:

- Consumers are more worried about short term expenditure rather than saving money in the long run.

- There is a lack of standardised testing and many products are still in the development stage yet more boaters are required to help test out these developmental products.

- There isn’t a strong enough stimulus for change – no government or legal obligation to switch from a product that works well to a less tested alternative, or for the antifouling paint industry to remove copper and zinc from its formulations as it was forced to do with TBT in 2001.

- Non-stick coating surface solutions such as silicone and hydrogel are relatively close to development whereas alternative organic coatings have much more research and development stages to get through and are far from getting to market any time soon.

Here at EFC, we still believe that your best and most reliable form of of environmentally friendly antifouling is the use of ultrasonic technology. Not only is it already available, it also saves you the hassle of annual antifouling. Check out our ultrasonic antifouling product kit brochure or contact our team today to find the perfect ultrasonic fouling control system for your boat and start your journey towards a more sustainable antifouling future.